High Quality Crusher Hammer For Sale | Factory Direct Price

OVERVIEW

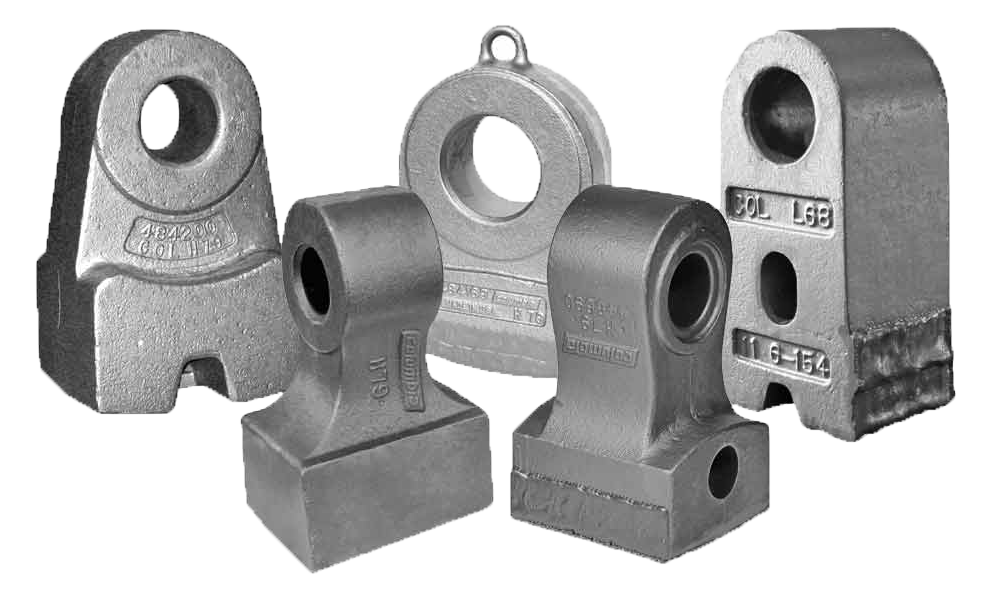

As a leading crusher hammer manufacturer, we specialize in the production and export of high-performance crusher mill hammers used in a wide range of industries, including mining, cement plants, and quarrying operations. With over a decade of manufacturing expertise and strict quality control, we ensure every hammer head delivers outstanding impact resistance, wear resistance, and long service life.

A crusher hammer (also known as a hammer head) is a key wear part used in hammer crushers and impact crushers. It strikes the material with high-speed rotation, breaking it into smaller sizes. These hammers endure harsh working conditions, making material quality and precision manufacturing crucial for optimal performance.

Material Options for Crusher Hammers

We offer a wide range of hammer materials to meet different working conditions:

High Manganese Steel (Mn13Cr2, Mn18Cr2):

Ideal for high-impact applications. Excellent toughness and work hardening properties.Alloy Steel:

Offers improved wear resistance and toughness. Commonly used in cement and limestone crushing.High Chrome Cast Iron:

Best for low-impact, high-abrasion environments. Excellent hardness and anti-wear properties.Bimetal Composite Hammers:

Combine high-chrome inserts with manganese or alloy steel bodies. Perfect balance between wear resistance and strength.

Crusher Mill Hammer Features and Benefits

Precision Casting or Forging – Ensures dimensional accuracy and consistent quality

Excellent Wear Resistance – Long-lasting performance even in harsh conditions

Strong Impact Toughness – Withstands heavy loads and repeated impact

Custom Sizes and Designs – Tailored to fit your crusher models and working conditions

Factory Direct Price – Save cost by buying directly from a trusted manufacturer

Fast Delivery – Short production lead time and global shipping support

Applications of Our Crusher Hammers

Our hammers are widely used in:

Mining Industry – Crushing hard rock, iron ore, gold ore, copper ore

Cement Industry – Crushing limestone, clinker, coal, gypsum

Quarrying Industry – Granite, basalt, gravel, sandstone crushing

Recycling Plants – Crushing construction waste and concrete

Crusher Hammer Quality Control

Our production process follows strict quality assurance steps:

Raw Material Testing

Spectral Analysis Before Melting

Precision Casting / Forging

Heat Treatment for Hardness Optimization

Surface and Internal Crack Detection

Dimensional Inspection Before Shipment

We are committed to delivering high quality crusher hammers that meet or exceed international standards. All wear parts are ISO certified and undergo rigorous factory testing before delivery.

Customization Services

We offer OEM/ODM crusher hammer services. Just send us:

Your drawing or part number

Working condition (material hardness, abrasiveness)

Crusher brand/model

Our engineering team will design and manufacture crusher hammers that perfectly match your operational requirements.

Why Choose Us as Your Crusher Hammer Manufacturer?

Whether you’re replacing hammers for a cement crusher or looking for bulk crusher hammer orders, we’re ready to serve with quality and reliability.

Order and Delivery

We support flexible order quantities and fast shipment options to meet your project timeline. Our products are exported worldwide to customers in Southeast Asia, the Middle East, Africa, Europe, and South America.

MOQ: 200 Kg

Lead Time: 7–15 Days

Packing: Wooden crates or customized according to request

Shipping: Sea, Air, or Express available

Request a Quote Now

Get a fast and accurate quote for your crusher machine hammer needs. Contact us today with your specifications, and our team will respond within 24 hours.

Precision Casting or Forging

Precision Casting or Forging