High Manganese Steel Crusher Hammers Supplier - Mn13 & Mn18

OVERVIEW

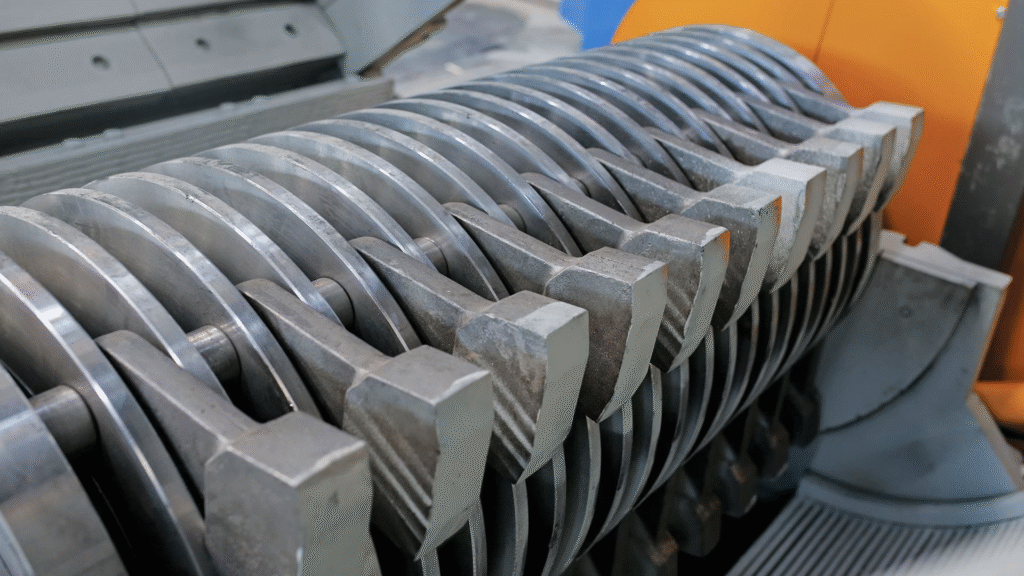

High manganese steel crusher hammers are critical components in hammer crushers used across mining, cement, quarrying, and aggregate industries. Among all the materials used in manufacturing crusher hammers, high manganese steel remains the most popular choice due to its unique work-hardening properties and exceptional wear resistance. At our factory, we specialize in manufacturing and exporting Mn13 and Mn18 high manganese steel crusher hammers, engineered for performance, durability, and cost-efficiency.

In this product page, we will cover everything you need to know about our Mn13 and Mn18 high manganese crusher hammers, including their features, applications, technical specifications, production process, and why we are your best supplier choice.

What is High Manganese Steel?

High manganese steel is an alloy steel containing 11–22% manganese and 0.8–1.2% carbon. Mn13 and Mn18 are two of the most widely used grades in the crusher wear parts industry.

Mn13 (Hadfield Steel): Known for its excellent toughness and work hardening ability. It becomes harder under impact or high-pressure conditions.

Mn18: Offers increased wear resistance and hardness, suitable for more abrasive and high-load applications.

These materials allow the crusher hammers to resist severe wear and impact conditions during operation.

Advantages of Mn13 & Mn18 High Manganese Crusher Hammers

1. Superior Wear Resistance

Both Mn13 and Mn18 high manganese crusher hammers have self-hardening properties. When subjected to high impact or pressure, the surface of the hammer becomes harder while the inner core remains tough and ductile. This results in extended service life.

2. High Impact Strength

Our manganese crusher hammers can withstand severe shock loads in impact crushers and hammer mills, making them ideal for crushing hard stones, ores, and recycled materials.

3. Work Hardening

The surface layer of Mn13 and Mn18 hammers work-hardens under continuous impact, forming a hardened skin while maintaining a tough interior. This dual-property performance makes them highly efficient in crushing operations.

4. Customizable Shapes and Designs

We provide OEM manganese crusher hammers in various shapes, including flat, T-shaped, twist lock, and customized drawings. You can send us your technical drawings or application requirements for customized hammer solutions.

5. Cost-Effective in Harsh Applications

Although high manganese crusher hammers may be more expensive than ordinary carbon steel parts, their long service life, reduced downtime, and lower maintenance costs make them more economical in the long run.

Applications of Crusher Hammers

Our Mn13 and Mn18 high manganese steel crusher hammers are used in various industries and crushers, including:

Mining: For crushing ores such as iron, copper, and gold.

Cement Plants: For crushing limestone, clinker, and raw materials.

Quarrying: For producing aggregates and crushed stone.

Power Plants: For crushing coal.

Construction Waste Recycling: For crushing concrete and demolition debris.

Technical Specifications

| Property | Mn13 | Mn18 |

|---|---|---|

| Manganese Content | ~13% | ~18% |

| Carbon Content | 1.0–1.2% | 1.0–1.2% |

| Hardness (as-cast) | 200 HB | 220 HB |

| Hardness (work-hardened) | Up to 500 HB | Up to 550 HB |

| Impact Toughness | High | Very High |

| Typical Applications | Medium wear environments | Heavy wear, high impact zones |

Manufacturing Process of Manganese Steel Crusher Hammers

Raw Material Selection

We use only high-purity raw materials and alloys to ensure chemical composition consistency in Mn13 and Mn18 hammers.

Precision Casting

Our crusher hammers are manufactured using lost foam casting or sand casting processes to achieve accurate shapes and consistent quality.

Heat Treatment

Strict heat treatment is applied to optimize grain structure and enhance mechanical properties. Quenching and tempering are used to balance hardness and toughness.

Quality Control

Every manganese crusher hammer undergoes rigorous quality inspection, including:

Spectrometer analysis

Hardness testing

Impact resistance testing

Dimensional accuracy checks

Product Customization Options

We offer:

Custom dimensions and shapes

OEM/ODM services

Logos or casting marks

Different manganese grades (Mn13, Mn18, Mn22)

Small or bulk orders

Why Choose Us as Your Crusher Hammer Supplier?

Factory Direct Price: No middlemen, better pricing.

Rich Export Experience: Serving clients in over 30 countries.

Strict Quality Control: ISO9001-certified facility with 100% inspection.

OEM/ODM Services: Custom designs based on drawings or samples.

Fast Delivery: Flexible production schedule and strong inventory.

Professional Support: Dedicated engineers and sales team.

Packaging and Shipping

We offer flexible packaging solutions depending on your destination and shipping method:

Export-standard wooden cases

Steel pallet packing

Customized labeling and logo branding

Sea freight, air freight, and courier service support

Customer Testimonials

“We’ve been using Mn18 crusher hammers from this supplier for over three years. The quality is consistent, and their service is professional.” – Cement Plant Manager, Vietnam

“Their Mn13 hammers perform very well in our quarry. We are happy with the wear life and price.” – Quarry Equipment Buyer, South Africa

Frequently Asked Questions

Q1: Can you provide samples of high manganese steel crusher hammers?

Yes, sample orders are welcome for quality evaluation.

Q2: What’s the MOQ (Minimum Order Quantity)?

We support flexible MOQ based on your project needs.

Q3: Can I get customized hammer designs?

Absolutely. Send us your design files or tell us the application, and we’ll help develop a suitable solution.

Q4: What is the expected lifespan of your high manganese steel crusher hammers?

It depends on the application and material, but Mn18 crusher hammers can last up to 3–5 times longer than ordinary steel.

Request a Quote

Looking for premium Mn13 and Mn18 high manganese steel crusher hammers? Contact us today for a free quote or more information. Our team will get back to you within 24 hours.

Email: [ljj2914@163.com]

WhatsApp: [+86-15057941949]

Website: https://crusherwearpartspro.com/

Get In Touch – Let’s optimize your crushing performance together!