Cone Crusher Wear Parts Manufacturer

OVERVIEW

We are a leading cone crusher wear parts manufacturer in China, committed to providing premium-quality parts at competitive wholesale prices to mining, quarrying, cement, and construction industries worldwide. With over 15 years of manufacturing experience and professional export services, we supply a wide range of OEM cone crusher wear parts, including mantles, concaves, feed cones, torch rings, and locking nuts, designed to maximize crusher productivity and service life.

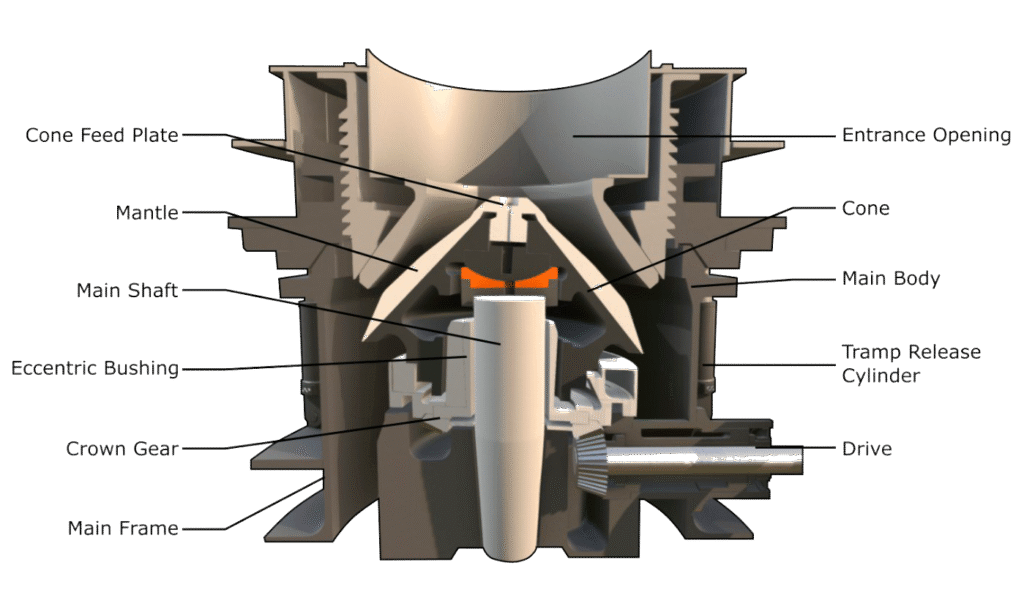

Cone crusher wear parts are essential components that endure extreme crushing forces and abrasive materials in rock and ore processing. They include the mantle, which rotates and crushes the material, and the concave, which forms the outer shell of the crushing chamber. These parts wear out over time due to constant friction, making timely replacement crucial to maintain crushing efficiency.

Materials We Use

We utilize advanced metallurgy and precision casting techniques to produce high manganese steel, chrome-molybdenum alloy steel, and bimetallic composite materials that deliver:

Excellent wear resistance

Superior impact strength

Extended service life

Lower maintenance costs

Common material grades we offer include:

Mn13Cr2 (13% manganese)

Mn18Cr2 (18% manganese)

Mn22Cr2 (22% manganese)

Custom materials upon request

Our Cone Crusher Wear Parts Range

We manufacture and supply a full range of cone crusher wear parts for various popular crusher brands, such as:

Metso® HP, GP, and MP Series

Sandvik® CH, CS, and H Series

Terex® Cedarapids MVP and TC Series

Symons® 2ft, 3ft, 4.25ft, 5.5ft, 7ft

Trio®, Kawasaki®, Telsmith®, and others

Our parts are 100% interchangeable with OEM components, ensuring perfect fit and reliable performance. Understanding Cone Crusher Mechanics

Common Cone Crusher Wear Parts We Supply

| Part Name | Function | Material Options |

|---|---|---|

| Mantle | Crushing surface against concave | Mn13Cr2, Mn18Cr2, Mn22Cr2 |

| Concave (Bowl Liner) | Stationary crushing surface | Mn13Cr2, Mn18Cr2 |

| Feed Cone | Guides material to crushing chamber | Mn13, Mn18 |

| Torch Ring | Locks mantle in place | High strength alloy |

| Locking Nut | Fixes mantle to the shaft | Alloy steel |

| Main Shaft Sleeve | Provides support and reduces friction | Hardened steel |

Applications of Our Cone Crusher Parts

Our cone crusher wear parts are widely used in:

Hard rock mining

Aggregates production

Iron ore processing

Granite and basalt crushing

Copper, gold, and limestone crushing

Cement and concrete recycling

Whether you operate a mining plant or a stone crushing line, our high-quality crusher wear parts can help improve uptime and reduce total cost of ownership.

Why Choose Us as Your Cone Crusher Wear Parts Manufacturer?

Factory Direct Price

We are a true cone crusher wear parts manufacturer, not a trading company. This allows us to offer unbeatable wholesale prices without middleman markups.Strict Quality Control

Every batch of cone crusher wear parts is inspected by our in-house QA team using spectrometers, hardness testers, and wear simulation machines.Customization Support

We provide custom design, reverse engineering, and OEM services tailored to your crusher brand and crushing application.Fast Delivery & Global Shipping

With a robust inventory and flexible production schedule, we ensure prompt delivery to clients across North America, South America, Southeast Asia, the Middle East, and Africa.Expert Technical Support

Our engineers can help you optimize wear part selection and provide failure analysis for maximum efficiency and cost savings.

OEM & Custom Orders Welcome

If you’re looking for custom-designed cone crusher parts, we support full OEM/ODM services with:

CAD drawings and 3D scanning

Sample analysis and duplication

Logo branding and custom packaging

Private mold development

Just send us your sample or drawing, and our engineers will provide a solution.

Packaging & Delivery

We pack all cone crusher wear parts in fumigated wooden boxes, with part numbers clearly labeled. We support:

FOB, CIF, EXW, DDP shipping terms

Sea, air, and express delivery

Port of loading: Ningbo, Shanghai, Qingdao

Lead time: 7–30 days depending on order volume.

Client Testimonials

“We’ve been sourcing cone crusher liners from [Your Company Name] for 5 years. Their products last longer than many OEMs and cost significantly less.”

— Carlos M., Chile

“High manganese concaves from this manufacturer perform well in our gold mining operation. Highly recommend!”

— Ali R., Saudi Arabia

Get a Free Quote Today!

Looking for a reliable cone crusher wear parts supplier? Contact us now for a quick quotation and technical support. We offer:

✅ Competitive wholesale price

✅ Fast global shipping

✅ Free consultation

✅ Customized solutions

Email: [ljj2914@163.com]

WhatsApp: [+86-15057941949]

Website: https://crusherwearpartspro.com/

Get In Touch – Let’s optimize your crushing performance together!