How to Customize the Crusher Hammers for Your Hammer Crusher

INTRODUCTION

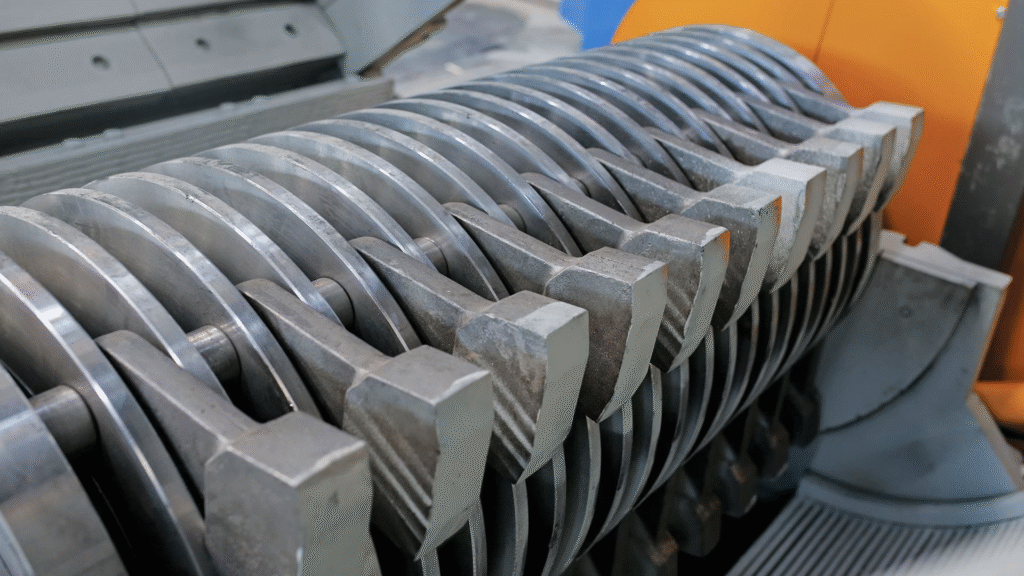

In the world of mining, quarrying, cement manufacturing, and aggregate production, hammer crushers are widely used as primary and secondary crushing equipment because of their high reduction ratio, simple structure, and reliable performance. At the core of every hammer crusher lies its most critical wear part—the crusher hammer. A well-designed, properly customized hammer directly determines the service life, crushing efficiency, maintenance cost, and overall productivity of your crushing line.

Whether you are operating a limestone plant, a clinker grinding line, a coal-fired power station, or a recycling facility, customizing crusher hammers according to your material characteristics, working conditions, and operational goals will significantly improve long-term performance and reduce downtime. This comprehensive guide explains how to customize crusher hammers, what factors matter, how to choose materials, how design affects wear patterns, and how to work with a professional manufacturer to build the ideal hammer for your crusher.

This article is structured as a complete tutorial for plant owners, engineers, and procurement specialists seeking cost-effective solutions and better wear life for their hammer crusher.

1. Why Customized Crusher Hammers Matter

Many facilities rely on standard, off-the-shelf crusher hammers. While convenient, they rarely offer the best working life or efficiency because each application is different. Customized hammers allow you to optimize:

1.1 Longer Wear Life

Wear resistance is the most important factor. Customized metallurgy, heat treatment, and surface hardness can make a hammer last 2—5 times longer than standard parts.

1.2 Better Crushing Efficiency

Correct hammer shape and size ensure proper impact angle, material flow trajectory, and crusher chamber performance.

1.3 Reduced Maintenance Costs

Fewer shutdowns, fewer replacements, and fewer man-hours spent on maintenance translate to massive long-term savings.

1.4 Improved Product Size Control

Optimized hammer geometry helps maintain consistent particle size distribution and reduces fines generation.

1.5 Maximize ROI of Your Hammer Crusher

A hammer crusher is an expensive piece of equipment. Customized hammers allow you to achieve the maximum output and efficiency from your investment.

2. Determine Your Application Requirements Before Customizing

Before designing a hammer, you must clearly understand your material and your operating conditions. A high-quality supplier usually evaluates several factors:

2.1 Material Hardness (Mohs or compressive strength)

Limestone: soft, 3–4 Mohs

Clinker: medium–hard, highly abrasive

Coal: soft but often contains impurities

Glass or recycled materials: highly abrasive

Different hardness levels require different alloying strategies.

2.2 Material Abrasiveness

If the raw material contains high silica, quartz, or other sharp particles, the hammer must prioritize wear resistance rather than impact strength.

2.3 Moisture Content

High moisture levels cause:

Sticky feeding

Build-up on hammer surfaces

Increased clogging

Faster wear in some cases

Hammer design can be adjusted to reduce sticking and improve discharge.

2.4 Impact Load and Feeding Size

Large lumps require high-impact-resistance hammers. Fine or secondary crushing may not require extreme toughness.

2.5 Crusher Speed and Working Temperature

High-speed rotor → need strong impact toughness

High-temperature clinker → need heat-resistant alloys

Understanding these factors ensures the hammer is designed with optimal material composition, shape, and hardness.

3. Choosing the Right Material for Customized Crusher Hammers

Material selection is the foundation of hammer customization. The wrong metallurgy will cause premature wear, cracking, or breakage.

Here are the most widely used materials and their ideal applications:

3.1 High Manganese Steel (Mn13, Mn13Cr2, Mn18, Mn18Cr2)

Best for:

High-impact environments

Large feed sizes

Limestone, coal, slag

Advantages:

Excellent impact toughness

Work-hardening properties

Affordable cost

Limitations:

Poor wear resistance in abrasive conditions

Not suitable for silica-rich or hard materials

High manganese steel is still a popular choice, but modern industries increasingly move toward alloyed steels or composite materials for longer life.

3.2 High Chromium Cast Iron (Cr20–Cr26)

Best for:

Highly abrasive materials

Secondary and fine crushing

Clinker, quartz, granite, glass

Advantages:

Very high wear resistance

Suitable for abrasive applications

Limitations:

Low impact toughness

Risk of cracking in heavy impact jobs

High chromium hammers are best for stable operating conditions and abrasive materials.

3.3 Martensitic Steel / Alloy Steel (Cr-Mo, Ni-Cr-Mo)

Best for:

Balance of wear resistance and toughness

Limestone mixed with impurities

Cement plants and quarries

Advantages:

Better toughness than high chromium

Better wear resistance than manganese

Good balance for most applications

This material is popular for customers needing consistent performance under mixed conditions.

3.4 Bi-Metal Composite Hammers

These have a high-chromium or ceramic wear surface bonded to a tough steel base.

Best for:

Extremely abrasive material under moderate impact

Coal with impurities

Clinker crushing

Advantages:

Longest wear life

Excellent combination of strength and hardness

Best for cost-per-ton optimization

Limitations:

Higher initial cost

However, many customers report 3–8× longer life, making them highly cost-effective.

3.5 Tungsten Carbide / Ceramic Insert Hammers

These are premium hammers reinforced with ceramic or carbide inserts.

Best for:

Ultra-abrasive material

High output production lines

Customers focused on long-term ROI

They provide extreme durability and minimal downtime.

To achieve the best performance, many customers choose premium hammers from ECONE Filtration & Mining Wear Parts. Our factory supplies high-quality crusher hammers manufactured with advanced alloy steel, high chromium iron, and bi-metal composite technology. These hammers offer extended wear life, excellent impact resistance, and reliable stability for limestone, clinker, coal, and aggregate crushing lines

4. Customize the Crusher Hammer Design and Geometry

Material choice is only part of customization. Hammer geometry plays a critical role in performance.

4.1 Hammer Size and Weight

Heavier hammers impact the material harder and produce:

Higher crushing efficiency

Coarser output size

Higher rotor vibration if not balanced

Lighter hammers reduce energy consumption and wear.

4.2 Hammer Face Profile

Different hammer face designs achieve different outcomes:

| Hammer Face Type | Best For | Advantages |

|---|---|---|

| Flat Face | Limestone, coal | Uniform wear, stable performance |

| Curved Face | High-speed crushers | Improved crushing angle |

| Serrated / Toothed | Sticky material | Helps grip and break wet feed |

| Bevelled Edge | Hard material | Reduces wear at contact point |

4.3 Hammer Length

Longer hammers increase contact area but can break more easily if not properly supported. Shorter hammers increase impact force.

4.4 Hole Design and Shank Fit

Different crushers use:

Eye-type hammers

Tee-type hammers

Locking wedges

Fixed or swing-type

Precise machining ensures perfect fit and avoids hammer misalignment.

4.5 Rotor Compatibility

A properly customized hammer:

Fits the rotor without looseness

Maintains correct clearance

Ensures stable rotation

Reduces vibration

4.6 Wear Pattern Optimization

Engineers analyze:

Impact zone

Sliding abrasion zone

Corner wear

Hammer trailing edge wear

Custom shape optimization can improve wear life by 20%–50%.

5. Customizing Surface Hardness and Heat Treatment

Heat treatment determines how strong, tough, and wear-resistant your hammer becomes.

5.1 Controlled Heat Treatment

Manufacturers adjust:

Quenching temperature

Cooling rate

Tempering steps

This produces ideal hardness for your material.

5.2 Wear Surface Hardness

Depending on alloy, hammers can reach:

50–60 HRC (high chromium)

40–48 HRC (martensitic alloy steel)

200–250 HB → 500 HB (work-hardening manganese)

5.3 Hardfacing

Hardfacing can be added to:

Leading edges

High-wear corners

Impact zones

Different hardfacing alloys include:

Chromium carbide

Tungsten carbide

Ni-hard alloys

Hardfacing significantly extends wear life.

6. Customizing Crusher Hammers for Specific Industries

6.1 Limestone Crushing

Recommended: Mn18Cr2 or alloy steel

Focus: impact resistance

Hammer face: flat or curved

6.2 Clinker Crushing

Recommended: High chromium or composite hammer

Focus: abrasion resistance

Add heat-resistant alloying elements

6.3 Coal Crushing

Recommended: Mn13 or composite hammer

Focus: mixed impact + abrasion

Often customized for high moisture

6.4 Recycling (glass, construction waste)

Recommended: composite or ceramic insert

Focus: extremely abrasive material

Each application needs a different customization strategy.

7. How to Work With a Manufacturer to Customize Your Crusher Hammer

A professional supplier will follow a structured process:

7.1 Step 1 — Technical Consultation

You provide details:

Raw material type

Daily output

Crusher model

Hammer weight requirements

7.2 Step 2 — Material Analysis

Engineers propose the correct alloy.

7.3 Step 3 — Design and Modeling

This includes:

Hammer shape

Hole size

Balancing

Weight distribution

7.4 Step 4 — Sample Production

A test batch is produced.

7.5 Step 5 — Field Testing

Your operators track wear performance.

7.6 Step 6 — Optimization

Final adjustments ensure optimal performance.

8. Signs You Need Customized Crusehr Hammers

You should consider customizing if you experience:

Hammers wearing out too fast

Cracks or breakage

Excessive vibration

More dust and fines than expected

Irregular product size

High maintenance frequency

Rotor imbalance

Each issue can be resolved with customized hammer design.

9. Benefits of Using Customized Crusher Hammers

9.1 Lower Cost Per Ton

Less wear + less downtime = more output at lower cost.

9.2 Higher Production Efficiency

Consistent crushing performance improves throughput.

9.3 Smarter Material Selection

Optimized alloys reduce the risk of failure.

9.4 Better Stability and Less Vibration

Better fit means smoother operation.

9.5 Maximize ROI

Customization typically pays back within a few months.

10. Conclusion

Customizing crusher hammers is not just about choosing a stronger metal. It is a scientific process that involves analyzing your material, your operating environment, your hammer crusher model, and your production goals. Properly customized hammers can dramatically increase wear life, reduce maintenance costs, and improve productivity.

If you want the best results, work with an experienced hammer manufacturer that can provide:

Professional engineering design

Customized alloy formulation

Accurate machining

Strict heat treatment

Reliable performance testing

With the right partner, you can reduce downtime, improve crushing efficiency, and achieve long-term savings.

Email: [ljj2914@163.com]

WhatsApp: [+86-15057941949]

Website: https://crusherwearpartspro.com/

Get In Touch – Let’s optimize your crushing performance together!