How to Extend the Lifespan of Crusher Wear Parts

INTRODUCTION

Crusher wear parts are critical components in mining, quarrying, cement, and recycling operations. Their performance and durability directly impact production efficiency, operating costs, and equipment downtime. As a result, plant operators and engineers are always seeking ways to extend the lifespan of crusher wear parts to reduce maintenance frequency and increase equipment uptime.

This guide provides comprehensive strategies for improving the longevity of jaw crusher wear parts, cone crusher wear parts, impact crusher wear parts, and other components—backed by expert advice, industry case studies, and best practices.

1. Understanding the Function of Crusher Wear Parts

Before diving into optimization strategies, it’s crucial to understand the role of wear parts in different crusher types:

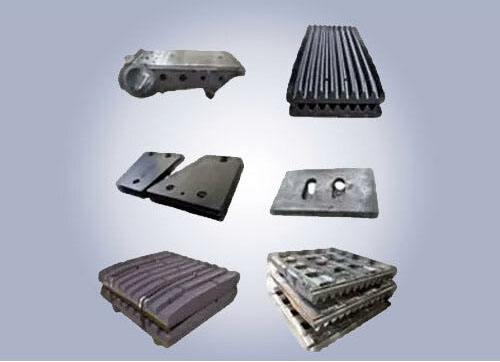

Jaw Crushers: Key wear parts include jaw plates (fixed and swing), cheek plates, and toggle seats.

Cone Crushers: Wear parts consist of the mantle, concave, and feed cone.

Impact Crushers: The main components are blow bars, impact plates (liners), and side liners.

These parts are exposed to extreme impact, compression, and abrasion forces, depending on the type of material being crushed (granite, limestone, basalt, etc.).

2. Selecting the Right Material for Crusher Wear Parts

One of the most important decisions in crusher wear parts selection is choosing the appropriate material:

a. High Manganese Steel (Mn13, Mn18, Mn22)

Offers excellent work-hardening properties.

Ideal for high-impact environments such as jaw crushers and impact crusher blow bars.

Mn13 and Mn18 are the most commonly used grades.

b. High Chromium Cast Iron

Superior resistance to abrasion and moderate impact.

Commonly used for impact crusher wear parts, including blow bars and impact plates.

c. Bimetallic Composites

Combine high toughness steel backings with wear-resistant inserts.

Cost-effective in specific applications like recycling and secondary crushing.

d. Carbide-Embedded Alloys

For extreme abrasion environments such as slag crushing or very hard ores.

✅ Tip: Always consult with your crusher wear parts supplier to determine the right material based on your application, feed material hardness, and crushing method.

3. Optimize Crusher Settings and Parameters

Incorrect feed size, CSS (closed side setting), or rotor speed can drastically reduce wear part lifespan. Here’s how to optimize:

a. Feed Size and Gradation

Avoid feeding oversized material.

Maintain uniform feed to reduce localized wear.

Use a pre-screening system to remove fines.

b. Crusher Speed and Power

Operate crushers at optimal speed.

Over-speeding increases wear; under-speeding decreases throughput.

c. Load Distribution

Uneven loading causes irregular wear.

Use feed distribution plates and monitors for even feed across the chamber.

4. Regular Maintenance and Inspection

Preventive maintenance is key to extending the life of crusher wear parts.

a. Daily Checks

Monitor wear patterns.

Check bolt tension, wear part movement, and any signs of cracking or deformation.

b. Weekly / Monthly Maintenance

Lubricate bearings, check liners, and inspect for loose components.

Measure wear part thickness and wear rate.

c. Use Wear Monitoring Tools

Employ ultrasonic thickness gauges or wear sensors.

Use visual indicators like wear lines or slots.

Understanding three different types of crusher maintenance

5. Proper Installation and Alignment

Poor installation can cause premature failure even in high-quality crusher wear parts.

Use torque wrenches to ensure correct bolt tension.

Check for seating and fitment—liners should sit flush.

Use backing compound (epoxy) where required, especially in cone crushers.

6. Training Operators and Maintenance Personnel

Human error is a leading cause of accelerated wear. Proper training includes:

Crusher operation techniques.

Recognizing abnormal sounds or vibrations.

Understanding part wear indicators.

Safe replacement and maintenance procedures.

7. Use Aftermarket Crusher Wear Parts from Trusted Suppliers

Choosing reliable crusher wear parts suppliers is vital.

Look for suppliers who offer:

Material traceability.

Customizable wear part designs.

Technical support and failure analysis.

Competitive pricing and fast delivery.

8. Implement Protective Measures

a. Feed Hopper Liners

Reduces impact and wear from falling rocks.

Protects primary crusher liners.

b. Dust Suppression Systems

Reduces abrasive particles in the air, protecting both parts and workers.

c. Chute and Transfer Point Liners

Reduces secondary wear before material enters the crusher.

9. Case Study: How One Quarry Extended Jaw Plate Life by 50%

Challenge: A European limestone quarry was experiencing jaw plate wear every 12 days.

Solution:

Switched from Mn13 to Mn18Cr2 jaw plates.

Modified feed chute to reduce drop height.

Trained operators on choke feeding method.

Result: Jaw plate life extended to 18 days—a 50% improvement with minimal cost increase.

10. Smart Inventory and Spare Parts Management

Avoid last-minute part replacements that lead to downtime.

Keep safety stock for critical wear parts.

Use parts tracking software to schedule replacements.

Evaluate past usage patterns for predictive stocking.

11. Consider Wear Part Upgrades and Innovations

Modern advancements in metallurgy and part design can increase wear part lifespan:

Thicker wear liners for high-wear zones.

Reinforced blow bar designs with inserts.

Twist-lock systems for easier liner changes.

Hybrid materials combining strength and wear resistance.

12. Don’t Ignore Crusher Design and Upstream Process

Crushers are part of a system. Optimizing upstream operations also contributes to longer crusher wear parts lifespan:

Adjust blasting to reduce oversize rocks.

Improve screening efficiency to maintain consistent feed size.

Use automatic tramp relief and overload systems to avoid damage.

Conclusion: Maximize ROI with the Right Wear Strategy

Extending the life of crusher wear parts is not about just using harder materials—it’s about the right material, right installation, right operation, and right maintenance.

Partnering with a professional crusher wear parts manufacturer—such as a Chinese supplier with decades of OEM experience—can significantly reduce your total cost of ownership (TCO) and increase production uptime.

Contact Us

Contact Us

Need help selecting the best wear parts for your crusher? Looking for custom solutions or bulk discounts?

Contact our sales and technical team today to explore how we can help you extend your crusher part lifespan and boost your plant productivity.

Email: [john@crusherwearpartspro.com]

WhatsApp: [+86-15057941949]

Website: https://crusherwearpartspro.com/

Get In Touch – Let’s optimize your crushing performance together!