Premium Alloy Steel Options for Your Crusher Wear Parts

In industries like mining, quarrying, recycling, and construction, crusher wear parts must withstand extreme abrasion and impact to ensure consistent production. Premium alloy steels offer a powerful combination of toughness, strength, and wear resistance—making them ideal for jaw plates, cone mantles, blow bars, hammers and liners.

Choosing the proper alloy steel can significantly reduce downtime, extend wear life, and improve overall operational efficiency. Below, we explore the top alloy options, their material composition, performance profiles, and application suitability.

High Manganese Steel (Mn12 / Mn14 / Mn18 / Mn22)

Also known as Hadfield steel, this alloy contains 11–14% manganese and a comparable carbon level (~1%), forming an austenitic microstructure that work-hardens under impact, dramatically increasing surface hardness during use. Starting at approximately 200 HVH (~20 HRC), the hardness can rise to 500 HV or more in operation

Advantages:

Exceptional impact toughness and ductility

Hardened surface under load that resists abrasion

Self‑healing microstructure avoids catastrophic failure

Typical Use:

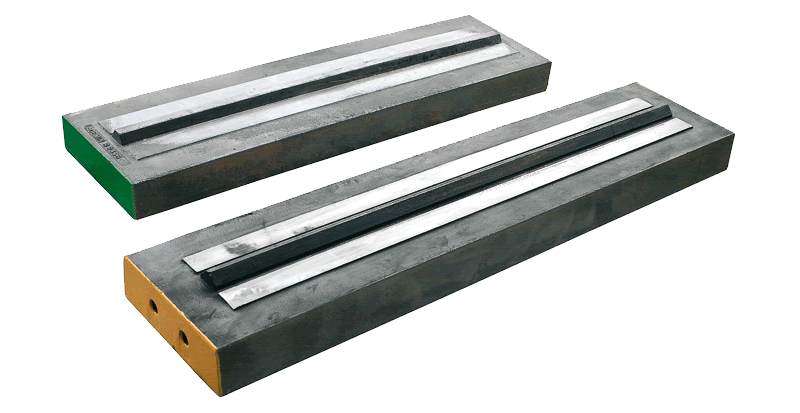

Jaw plates, cone mantles, cheek plates, gyratory liners

Best for primary crushing where heavy impact strikes

Trade‑offs:

Lower abrasion resistance compared to high‑chrome materials

Frequent maintenance may be required in abrasive environments

High Chromium Iron / High Chrome Alloy Steel (Cr15–Cr26)

These alloys contain 15–30% chromium, with higher carbon to create hard chromium carbide phases. The resulting hardness commonly reaches 58–65 HRC, offering outstanding wear resistance in abrasive but low-impact settings

Advantages:

Very high resistance to abrasive wear

Longer service life in secondary and tertiary crushing stages

Excellent for sharp‑edged or silica‑rich feed materials

Limitations:

More brittle and less tolerant to impact loads

Can fracture under tramp metal or oversized rocks

Martensitic Alloy Steel

This class of alloy steel often combines moderate chromium, molybdenum, or nickel with rapid quenching to create a martensitic microstructure. Typical hardness ranges from 44 to 57 HRC and impact strength from 100–300 J/cm²—positioning it between manganese and chrome steels

Advantages:

Balanced wear resistance and impact toughness

Better fracture resistance than high‑chrome irons

Applications:

Blow bars in impact crushers

Hammers in hammer crushers

Areas with moderate abrasion and occasional shock loading

Carbide-Reinforced Alloy Steel (TIC Inserts, Ceramic Composite)

For highly abrasive environments, TiC-reinforced or ceramic‑embedded alloy steels are used. These inserts deliver superior hardness (above 85 HRC) and can extend lifespan up to 2–3× compared to standard alloys.

Advantages:

Exceptional wear resistance on abrasive rock

Significantly longer wear life, minimizing downtime

Applications:

Jaw plates, cone liners, blow bars in silica-rich or hard rock crushing

Ideal for high-volume continuous operations

Considerations:

Higher upfront cost, but lower cost-per-ton over lifecycle

5. Hybrid Alloy Strategies (Layered Designs, Mixed Use)

Combining alloys strategically can optimize both performance and cost. For instance, using tungsten carbide only in high-wear zones, while retaining manganese steel for structure reduces cost while capturing key wear benefits. Hybrid part designs may deliver 70% of carbide benefits for 30% of cost.

Performance & Lifespan Comparison

| Material / Alloy Type | Hardness | Impact Resistance | Wear Resistance | Typical Lifespan |

|---|---|---|---|---|

| High Manganese Steel (Mn18Cr2) | 50–55 HRC | Excellent (★★★★★) | Good | 500–800 hours |

| High Chromium Iron (Cr26) | 58–65 HRC | Low (★★★☆☆) | Very High | 800–1,200 hours |

| Martensitic Alloy Steel | 44–57 HRC | Moderate | Moderate to High | 300–800 hours |

| TiC‑reinforced Alloy / Ceramic | >85 HRC | Low–Moderate | Extremely High | 1,500–2,000+ hours |

Selecting the Right Alloy: Key Considerations

Crusher Type

Jaw Crushers: Benefit most from work-hardening manganese steels that handle high compressive loads

Cone Crushers: May use manganese or martensitic alloys depending on feed hardness

Impact / Hammer Crushers: Often require high-chrome or TiC-inserted alloys to resist abrasion

Material Characteristics

Soft, impact-heavy feed (e.g. limestone): Manganese steel performs well

Highly abrasive feed (e.g. quartz, granite): Chrome iron or ceramic composites better suited

Mixed feed or tramp metal risk: Manganese safer than brittle chrome

Cost vs. Wear Life

Lower-cost manganese is economical for short-term or mobile operations.

Higher-cost premium alloys (e.g. TiC) offer better ROI where downtime costs are critical

OEM & Custom Alloy Steel Solutions at CrusherWearPartsPro.com

At CrusherWearPartsPro.com, we offer both standard OEM materials and engineered custom alloy solutions:

Standard Alloys: Mn13Cr2, Mn18Cr2, Cr26 for common crusher models

Tailored Alloys: Customized blends (Ni-Cr-Mo, microalloyed steels) based on your specific feed and crusher

Hybrid Inserts: Carbide-enhanced alloys and selective reinforcement for high-wear zones

Advanced Processing: CAD design, heat treatment, and strict quality control ensure optimal performance

Our engineers help determine the best material based on feed analysis, crusher type, and service expectations, delivering reliable, high-performance wear parts.

Benefits of Using Premium Alloy Steels

Extended Wear Life: Less frequent replacements reduce downtime

Improved Efficiency: Consistent crushing performance and output

Cost Savings: Fewer part changes lower maintenance and replacement costs over time

Enhanced Safety: Stronger, more predictable wear behavior reduces risk of catastrophic failure

Customized Solutions: Alloy selection tailored to your specific operation ensures better ROI

Conclusion: Making the Smart Choice

Selecting the right alloy steel for your crusher wear parts is critical. For impact-heavy primary crushing, manganese steel remains the go-to choice. For highly abrasive materials, high chrome or ceramic-reinforced alloys deliver longer service life. In demanding, mixed-feed environments, hybrid or custom alloy designs may offer the best balance of toughness, wear resistance, and cost efficiency.

At CrusherWearPartsPro.com, we combine material expertise, flexible alloy options, and strict quality control to deliver wear parts that meet your operational expectations. From OEM replacement components to custom engineered alloys, we help you enhance equipment uptime and productivity.

Ready to upgrade your crusher’s wear performance? Contact us today or request a custom quote tailored to your crusher and feed conditions.