How to Choose the Right Material for Crusher Wear Parts

INTRODUCTION

In the competitive world of mining, quarrying, cement, and construction, the performance and longevity of crusher wear parts directly influence operational efficiency and total cost of ownership. Whether you’re operating jaw crushers, cone crushers, impact crushers, or hammer mills, your choice of wear parts supplier can have a significant impact on production output, downtime, and maintenance costs.

In recent years, Chinese crusher wear parts manufacturers have gained a solid reputation on the global stage. With advancements in metallurgy, quality control, and machining capabilities, China is no longer just a “cheap alternative”—it is often the preferred source for premium, affordable, and reliable crusher wear parts.

This article explores in detail why choosing a Chinese manufacturer for your crusher wear parts is a smart move for companies around the world. We’ll cover quality, price, customization, technical expertise, logistics, OEM support, and more.

1. Global Competitiveness of Chinese Manufacturers

1.1 Rapid Industrial Development

China’s industrial base has expanded tremendously over the last three decades. From raw steelmaking to advanced alloy casting and precision CNC machining, many foundries and machining shops in China now match or exceed Western standards.

China is also home to entire supply chains, meaning everything from manganese ingots to final machining and heat treatment can be completed under one roof. This reduces lead times, lowers costs, and ensures full control over product quality.

1.2 Export-Focused Mindset

Many Chinese crusher wear parts factories are export-focused, meaning they are fluent in international standards such as:

ASTM A128 (Manganese Steel)

ISO 9001 and ISO 14001

CE marking and European technical standards

Their teams are often skilled in English communication, CAD-based design, and international logistics, making it easier for foreign buyers to collaborate.

1.3 Quality Management and Certifications

Modern Chinese foundries have invested in quality inspection equipment such as:

Spectrometers for chemical analysis

Brinell and Rockwell hardness testers

Metallographic analysis stations

Ultrasonic and magnetic crack detection systems

Many offer 3.1 MTC certificates, batch traceability, and detailed inspection reports as part of standard procedure.

2. Cost Advantage Without Compromising Quality

2.1 Lower Labor and Raw Material Costs

One of the key reasons to work with a crusher wear parts supplier in China is the cost advantage. While global inflation has affected raw material prices everywhere, labor and production costs in China remain relatively low. This allows Chinese manufacturers to offer competitive pricing without sacrificing quality.

For example:

Manganese steel jaw plates in China can cost 30–50% less than equivalents in Europe or North America

High chrome impact bars are readily available and competitively priced

2.2 Bulk Production and Economies of Scale

Many mining wear parts factories in China operate at large scale, producing thousands of tons of liners and components monthly. This scale brings economies that smaller Western foundries cannot match.

You benefit from:

Lower unit cost

Faster lead time for standard parts

Reduced tooling/setup fees for OEM customization

3. Wide Range of Materials and Components

Chinese manufacturers offer one of the widest material portfolios for crusher wear parts:

13%, 18%, 21% manganese steel (ASTM A128)

Martensitic steel

Chrome white iron (20–27% Cr)

Ceramic matrix composites

Bimetallic castings

Custom Ni-hard and Cr-Mo alloy solutions

Common parts include:

Jaw plates for jaw crushers

Cone crusher liners (mantle and bowl)

Impact crusher blow bars and liners

Hammer crusher hammers

VSI rotor tips and anvils

Cheek plates, side liners, toggle plates, and more

4. Customization and OEM Services

4.1 Reverse Engineering

Most reputable Chinese suppliers offer reverse engineering services. You can send a sample or drawing, and their engineers will create CAD models, simulations, and even performance upgrades.

4.2 OEM & Private Label Manufacturing

Whether you’re a dealer, OEM, or end-user, Chinese factories can produce parts under your brand. You can request:

Custom logos and part numbers

Special alloy combinations

Coating and surface treatment (e.g., hard facing, chrome spray)

Unique packaging and branding

5. Advanced Foundry Technology and Equipment

Top-tier Chinese foundries now utilize:

3D sand printing for precision molds

Lost foam casting for complex geometries

Automated molding lines for consistency

Vacuum casting for high-chrome parts

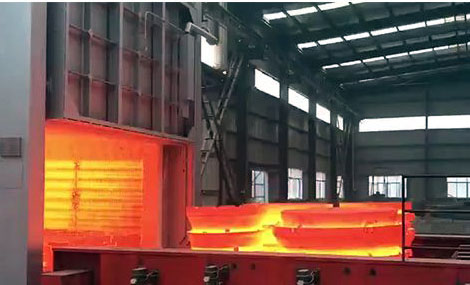

Heat treatment furnaces with temperature control up to 1100°C

This means Chinese factories can meet tight tolerances and deliver parts with predictable wear life.

6. Faster Lead Times and Global Shipping Support

6.1 In-House Logistics Teams

Export-oriented suppliers often have in-house international logistics teams who:

Handle customs documentation (Bill of Lading, Certificate of Origin, etc.)

Offer flexible shipping methods (LCL, FCL, Air Freight)

Partner with forwarders like DHL, Maersk, COSCO, and CMA CGM

6.2 Global Distribution Warehouses

Many large suppliers have overseas distribution points in:

Europe (Germany, UK, Spain)

USA (California, Texas)

South America (Chile, Peru)

Australia and Southeast Asia

This allows for local support and faster replenishment for key wear parts.

7. Real-World Case Studies

7.1 South American Mining Operation

A gold mine in Peru switched to a Chinese supplier for jaw and cone crusher parts. Results:

Cost savings of 38%

Improved wear life by 22%

Delivery time reduced from 6 weeks to 3 weeks

7.2 European Aggregate Plant

An aggregate producer in Germany used Chinese high chrome blow bars for impact crushers. They reported:

Longer intervals between shutdowns

Consistent performance across batches

Positive feedback from maintenance teams

7.3 Australian Quarry

The quarry partnered with a Chinese OEM for custom liners. Benefits:

Local warehouse for fast delivery

Quarterly engineering reviews

Improved throughput by 15% after redesign

8. Common Misconceptions Debunked

“Chinese parts are low quality.”

“Communication is difficult.”

“Lead time is too long.”

9. How to Choose the Right Chinese Crusher Wear Parts Supplier

Checklist:

ISO-certified production

Proven export track record

In-house quality control lab

Experienced engineering team

OEM capability

Transparent communication

References from existing international clients

Request sample reports, testing certificates, and case studies before placing bulk orders.

Conclusion

Partnering with a Chinese crusher wear parts manufacturer can provide significant advantages in cost, quality, lead time, and flexibility. As China continues to lead in foundry technology and supply chain integration, more global buyers are shifting their sourcing to reliable Chinese partners.

From manganese steel jaw plates to high chrome blow bars, China offers a full spectrum of crusher spare parts that meet global performance and compliance standards.

If you’re looking for a trusted supplier, responsive support, and engineered performance, consider working with a crusher wear parts factory in China—it might be the smartest supply chain decision you’ll make.

Need help selecting the right parts or requesting a quote? Contact our team at Econe Industry Co., Ltd. for expert advice, fast turnaround, and factory-direct pricing.

Email: [ljj2914@163.com]

WhatsApp: [+86-15057941949]

Website: https://crusherwearpartspro.com/

Get In Touch – Let’s optimize your crushing performance together!

Hello.This post was really fascinating, especially since I was browsing for thoughts on this issue last Thursday.